Ford Motor has extended production halts at four U.S. plants and one in Canada for an additional two weeks, the Wall Street Journal reports, due to ongoing semiconductor shortages. The outages will reportedly impact production of the F-150 truck which the firm had previously kept going with reduced content.

Global semiconductor supplies continue to grow rapidly, as discussed in Panjiva’s research of April 21, but a reduction in orders during 2020 has led manufacturers to prioritize other customers. A call to arms by the Biden administration is unlikely to yield an increase in availability within the time frame of a few months.

The closures will have a knock-on effect to the rest of Ford’s supply chain. Panjiva’s data shows the firm had ramped up imports in March, with growth of U.S. seaborne imports linked to the firm having increased by 67.8% year over year and by 39.2% compared to March 2019.

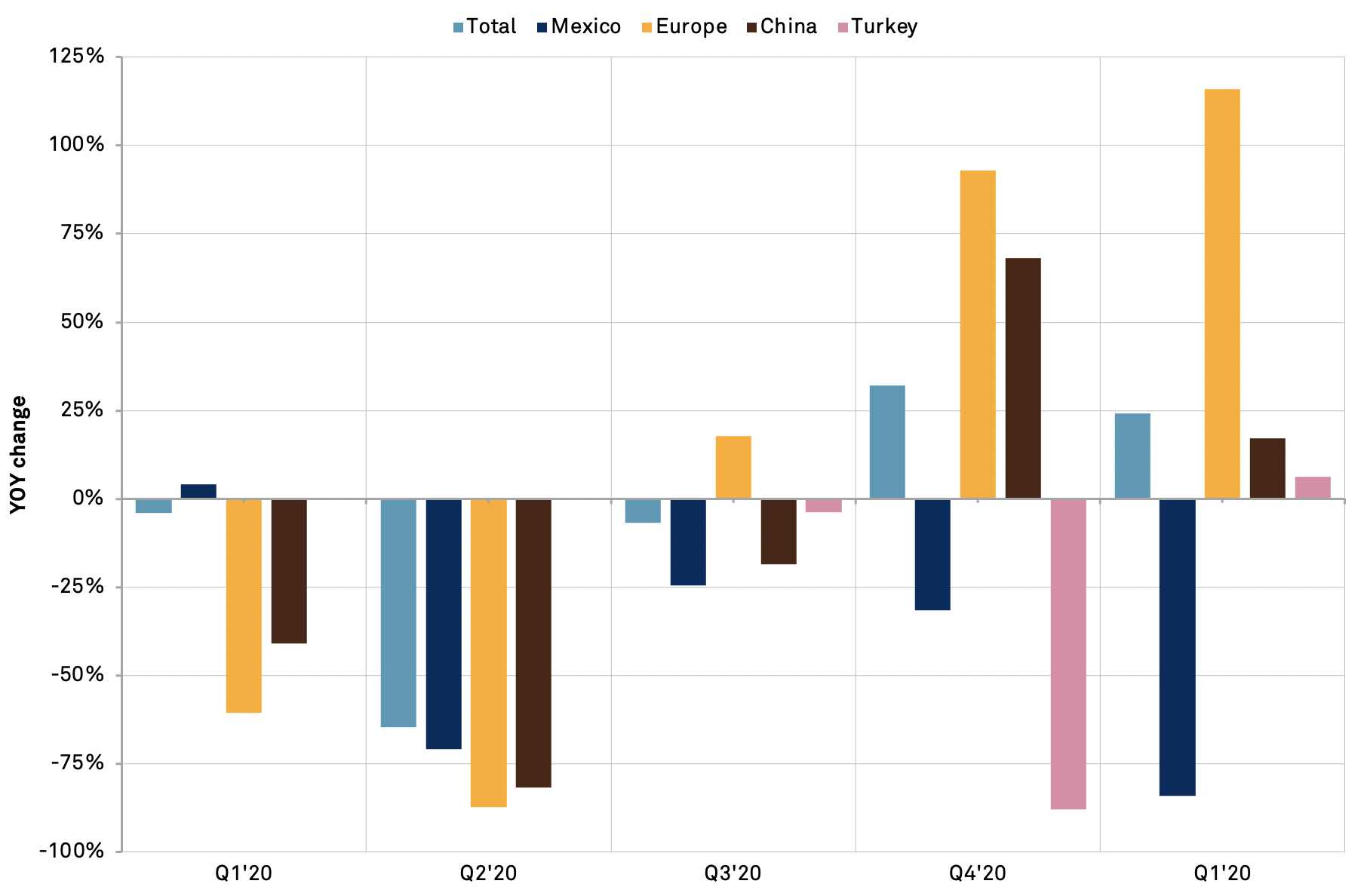

That brought the Q1’21 total to a 24.1% increase, raising the risk of oversupply of non-semiconductor parts. The ramp up in Q1’21 has been led by shipments from Europe which climbed 116.0% higher, while shipments from China rose by just 17.1% and those from Mexico declined.

Source: Panjiva

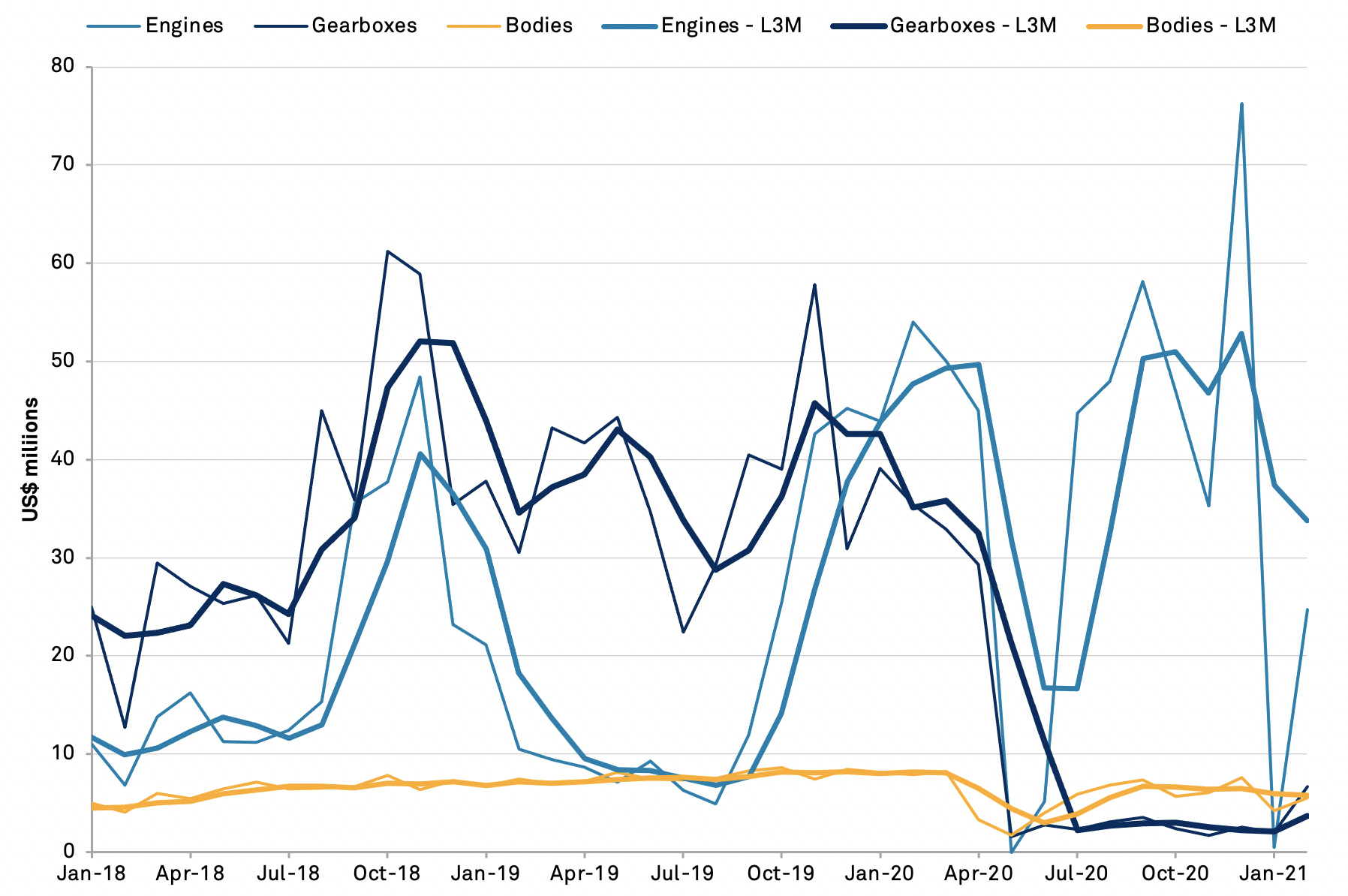

Ford’s Mexican parts operations have slowed significantly however, possibly reflecting a wider rearrangement of the supply chain. Shipments in total fell by 53.5% year over year in February after dropping by 80.7% in January. The decline has included reduced shipments of gearboxes and engines which declined by 81.1% and 54.3% respectively in February while shipments of body components dipped by 29.7%.

Source: Panjiva