Automakers reporting results for the three-month period ended Sept. 30 have had a common thread: the impact of ongoing global chip shortage. Ford CFO John Lawler noted the challenges facing the industry during the company’s Oct. 27 earnings call, saying they saw “lower-than-anticipated improvement in chip availability in the second half of the year,” and adding, “[W]e are doing everything we can to get our hands on as many chips as we can.”

Panjiva data shows that imports of semiconductors and printed circuit boards (PCB) increased by 39.7% in Q3. Some of this is likely related to pandemic recovery, with imports in the same quarter against 2019 up by 34.8%, but shows a strong surge in demand regardless.

Mainland China represented the largest source of semiconductors and PCBs into the U.S., accounting for 30.4% of the total in 2020. This fell to 26.7% of the total in the first nine months of 2021, with imports from the region increasing by 20.4% in Q3 compared to 2019. Imports from mainland China had already been declining before the pandemic, likely due to the U.S.-China trade dispute, so the surge of demand following the end of COVID-19-related lockdowns increased imports from a lower base.

The biggest beneficiary of the chip demand boom is likely Japan, whose share of PCB and semiconductor imports in the first nine months of 2021 rose to 13.8% of the total. This is up from 12.1% in 2020 and corresponds with a 72.2% increase in Q3 against 2019. The recent uptick may be associated with the recovery of Renesas Electronics facilities, discussed in Panjiva’s research of Oct. 5, and may represent an area that is well-positioned to increase manufacturing capacity.

Source: Panjiva

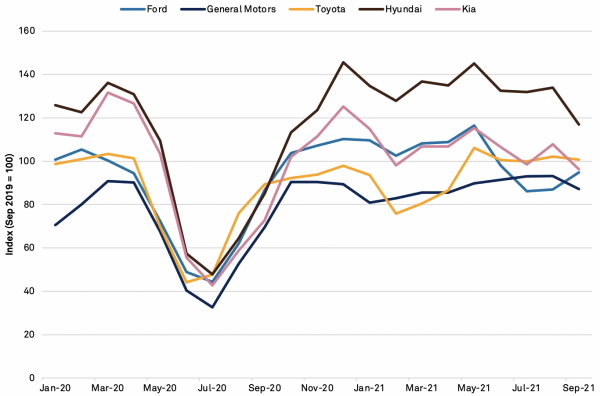

There were differences in outcomes between some of the major automakers, however. Japan’s Toyota and South Korean automakers Kia and Hyundai reported increases in revenue of 11.4%, 8.8% and 4.7% year over year, respectively. U.S.-based Ford and GM saw revenues fall 4.8% and 24.5%, respectively.

Toyota emphasized the impact of the chip shortage and COVID-19 on their production, with CFO Kenta Kon saying in the Nov. 4 call that “local production plants had to be shut down, and the parts supply had limitations” but recognized their suppliers and plants for their “great efforts to supply as many cars to our customers as possible”

Ford and GM were more troubled, with year-over-year declines in revenue. One of the common denominators between the companies is an increase in inventory, with Ford’s growing by 27.6% year over year in Q3 and GM’s up 32.9% year over year. This may be due to a strategy that the two firms have been using to cope with the shortage, which is producing vehicles without the missing chips and storing them for later. GM CFO Paul Jacobson said they had a “higher work-in-process inventory related to vehicles produced without certain modules,” alluding to this approach. The uptick in inventories could also have some supply chain impact down the road, potentially leaving automakers with old inventory if chip supplies don’t surface.

Ford thinks the shortages will continue for the foreseeable future. CFO Lawler said, “[W]e see that running through 2022. It could extend into 2023, although we do anticipate the scope and severity of that to reduce.” The timeline to resolve the issue comes back to the core of the chip shortage in the first place, which is the lack of capacity in older, larger chips used by the automotive industry. The two- to three-year timeline in recovering from the shortage matches the time expected for new production to come online.

Source: Panjiva

Panjiva data associated with automakers show that U.S. seaborne imports from overseas, mostly excluding USMCA countries, have not recovered beyond 2019 levels even after showing strong increases from 2020. These imports likely represent more technological components versus drivetrain, as well as some completed vehicles from Japanese manufacturers. The only automaker out of the five to see increased Q3 imports against 2019 was Hyundai, up 5.1%, while Kia saw imports by volume fall by 5.1% in the same period. Imports linked to Toyota declined by 10.7% in Q3 against 2019 but posted a recovery over 2020, still hampered by supply chain issues.

Ford and GM saw imports in Q3 fall by 11.5% and 9.8% year over year respectively, likely representing the gap in goods needed to finish some of their work-in-progress inventory. Ford may be using the chip shortage as a chance to change its business model, pushing make-to-order as the preferred alternative to manufacturing based on projected sales and sending to dealers. This practice would help Ford’s supply chain by avoiding the production of cars that are not in demand. Ford President and CEO James Farley said during the earnings call that a make-to-order system is “lower-cost,” adding, “There’s less parts hanging around. We can manage our industrial system and our manufacturing in a leaner way.” This illustrates the kind of opportunity the shortage is presenting to automakers, which are always looking to operate more efficiently.

Source: Panjiva