The discipline of Supply Chain Management stands to gain heavily from advances in technology – from blockchain, internet of things, and machine learning, companies will be able to leverage new techniques in the next decade. This report details a variety of upcoming trends in supply chain and logistics that Panjiva customers should be aware of. This report has been produced with the kind assistance of Brian Partridge of 451 Research, a sister organization of Panjiva within the S&P Global Market Intelligence business.

Logistics transparency – the key driver for technological change

If paper bills of lading and manual tracking were not already obsolete – technological advancements in the 2020’s will spell the end of pen and paper shipping. While digitally enabled systems enhance efficiency for the carrier, a major benefit for all users is the resulting transparency. Where before only the cargo owner could track their shipments, an encrypted, distributed ledger technology like blockchain allows any permissioned participant in the network to view the whole network with immutable transaction data.

This explosion of data presents opportunities to optimize the entire network, sending savings to all participants. In a recent study conducted by FourKites and the Trading Partner Alliance, three months of data at four facilities was reviewed to show that dwell times could be reduced by increasing network transparency – an average of 7.2% across the four companies in the study. Automated scheduling systems were hobbled by only looking at the maximum available time slots per day rather than the capacity of the warehouses and network as a whole.

Transparency is also being demanded by parties that previously didn’t consider a product’s supply chain. Modern, environmentally conscious consumers not only want to know where a product came from, but they want to know how it was manufactured, and the social and environmental effects of their purchase.

Tracking a vegetable grown thousands of miles away through numerous intermediaries and processors is already a herculean effort – see the section on blockchains below – but carriers that are able to do so also have the ability to differentiate based on a growing concern for the climate.

Global shipping accounts for 3.1% of global carbon dioxide emissions – a topic that is on the mind of the International Maritime Organization with changes in sulfur emissions that have gone into effect, as discussed in Panjiva 2020 Outlook for the logistics industry. The IMO has a number of other initiatives to reduce the climate impact from shipping, including increasing the energy efficiency of new ships, cooperation with ports to give access to alternative fuels, and proposing voluntary measures for states, carriers, and ports to take to reduce impact.

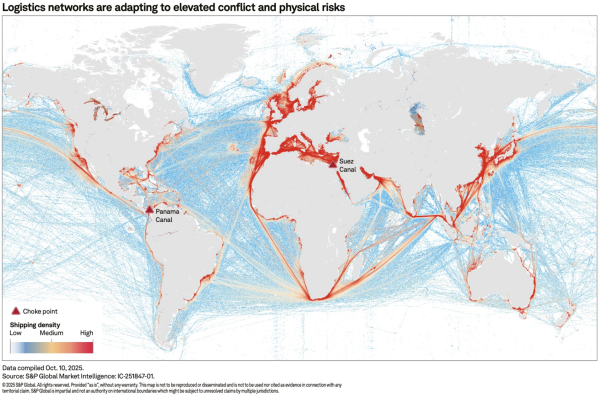

As carriers move to reduce these pressures, the trend will likely be a decrease in long shipments. Shorter shipping routes have less environmental impact and may be able to use smaller ships. Shorter routes are also easier on alternative propulsion mechanisms like electric or wind drives and could enable leaner supply chains through faster lead times.

Internet of Things foundational to supply chain visibility

Internet of Things is shorthand for a wide range of technologies that combine machine connectivity, sensors, communications networks with data analytics and applications to digitize the physical world. In other words the assets in the physical world can be combined with existing digital information assets (CRM, SCM, ERP) to create more impactful insights and outcomes.

451 Research’s Internet Of Things survey conducted in 2019 revealed that ‘Optimizing Operations’ is the most popular use for IoT data collected by firms (68%) and over half of those respondents are using IoT data to optimize supply chain/logistics operations.

The same survey found that the return on investment for IoT projects was generally positive, with more gains coming from manufacturing and retail sectors. Companies that characterized themselves as early adopters and digital leaders also reported higher returns – over half of those firms reporting positive results. Notably the size of the firm was less important – smaller firms are theoretically more agile and benefit from automation multiplying the impact of the workforce. It’s likely however that there are scale economies in investment including the ability to reach a tipping point of effectiveness earlier.

Source: Panjiva

Artificial Intelligence and Machine Learning are essential, but difficult to source

There’s an explosion of data generated by new booking and logistics platforms. Indeed, 451 Global IoT Market Monitor forecasts that by 2024 there will be 13.8 billion connected IoT endpoints. That’s generated a need for new data skills in the supply chain workforce.

Effectively leveraging large data capabilities requires investments in information technology and analytical skill sets – increasingly including data science capabilities.

The 451 Research Voice of the Enterprise IoT survey for 2019 indicated that the top two barriers to firms ability to capture and use IoT data were the fact that IoT sources create too much data to fully capture and analyze (36%) as well as raising cleaning, management, and complexity concerns (33%). Of course, building skills in these areas will help most organizations.

The range of skills needed should not be underestimated in order to effectively collect, store, and serve data. There are three broad areas to assess.

First, proficiency in big data technologies like Hadoop, Spark, Hive, or other distributed systems are essential if building a data capability from scratch, while strong technology teams will focus on production ready, scalable tools.

451 Research’s Voice of the Enterprise: Digital Pulse survey conducted in 2019 showed that AI and machine learning are expected to be the most transformational technology over the next five years, while the industries currently using the technology most widely are (perhaps unsurprisingly) Software & IT Services (44%) and Healthcare (41%).

Second, Analytical teams are responsible for interpreting, presenting, and understanding the business implications of the data gathered. As a result, with a mix of domain knowledge, business intelligence, and programing skills are ideal.

Finally, firms that choose to make data a core competency need to invest in a data science team to enable predictive and prescriptive modeling of their applications. Compared to the analysts – who specialize in descriptive analytics – predictive and prescriptive analytics allow forward looking decisions to be made with more confidence, as well as building tools that can optimize business operations.

These three teams can collaborate to integrate large data sets from the firm’s supply chain as well as integrate secondary, enriching data. Finance and other industries like retail have already realized the power of high capability data teams while logistics and supply chain firms that build world class capabilities may have a leg up as technology expands.

The hiring and retaining of talent was challenging to 84% and 69% respectively of respondents in SCM World’s Nov 2016 Future of Supply Chain survey, indicating the difficulty of building a strong data team.

Apparel retailer H&M has made significant investments in AI technologies for their supply chain, Supply Chain Dive reports, with the firm’s Head of AI, Arti Zeighami stating that analytics is about “how you make sure the right product is in the right place at the right time and is transported into the warehouse,”.

Furthermore Zeighami has noted that using data analytics has led the firm to “see a significant impact. And we’re thinking of how can we do this for our entire production?” H&M is also of note for promoting product transparency – showing the factories and locations of their suppliers.

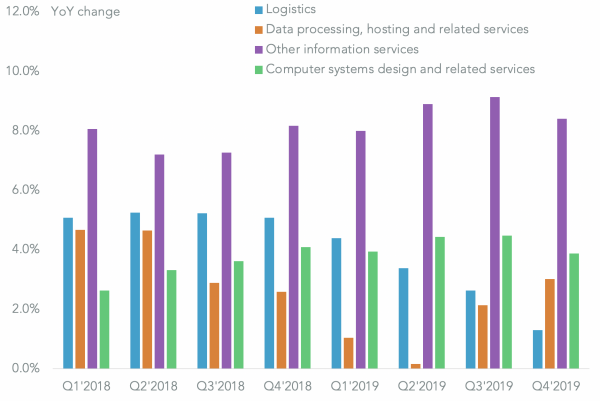

The major challenge, of course, comes in finding the engineering, analytical and data-science people to fill the new roles. There’s significant competition for staff witnessed by the surge in hiring of “other information services roles” which has grown by 8.3% annually over the past three years, Panjiva’s analysis of BLS data shows. By contrast the logistics industry has seen growth of just 3.3% while more mundane data-processing roles have grown by just 3.2%.

Source: Panjiva

Supplier Networks – a different way of looking at trade

One area where data science teams can make an immediate impact is in restructuring data into graph networks. Graph networks transform data on shipments into nodes (entities) and edges (shipments). Each shipment has a shipper and a consignee, allowing you to relate the two entities together via the shipment. Supply chain data is already well structured for this application as enterprise resource planning (ERP) systems already track transactions to a granular level.

Network analysis allows the consideration of supply chains from a different angle – for example concepts like centrality, connectedness, and neighborhoods can be analyzed. Graph analysis can let an organization delve deeper into its supply chain, identifying areas where second tier suppliers or customers may pose risks.

Node properties including clustering and power can be tracked alongside network properties like complexity, while adding a time dimension can allow tracking the evolution and emergence of nodes in the system. The resulting anomaly detection can reveal new opportunities as well as identify risks.

One of these cases is a “supply chain diamond” where two suppliers to a firm in turn share the same supplier – while the company may think their sourcing risk is distributed, the 2nd level supplier magnifies their risk.

Another use case is to test supply chains for robustness – i.e. the amount by which a network would change if a node – or series of similar nodes – were removed. Networks and nodes can be ranked by these factors to identify higher level patterns or classify companies.

Source: Panjiva

Robotics – lead time reduction can be powerful

Coming back to the physical aspect of supply chains, robots that can take commands from machine learning models can boost efficiency and productivity, shorten lead times, as well as allow for more uptime in manufacturing environments.

Producing small batches locally and cheaply could reduce the demand for large, long distance shipments. Commercial inkjets are an example of technology enabling smaller, customized batches by reducing downtime and setup costs. Canon recently celebrated 250 installs of their inkjet printing press, Printing Impressions reports, showing the success of these technologies in enhancing or replacing legacy offset printing.

Additive manufacturing, including 3D printing, has brought this revolution to another dimension. It can be used to create custom components where before it would be too expensive. Additionally, on-demand print runs have the potential to lower parts inventories and transform businesses that rely on just in time supply chains.

With reduced lead times, precautionary inventories can be lowered and cash reclaimed from the balance sheet, as well as knowing that potential replacements could be created locally.

Adidas’s experience with its Speed Factory shows that these technologies are still in their infancy, after the firm took the decision to close its robotic shoe factories in the U.S. and Germany.

These factories were designed to reduce the travel time between Asia and Adidas’s western markets, and level the cost of labor between the two regions. Yet, Techcrunch reports that the factories were “difficult to quickly reconfigure or repurpose, since it takes specialty knowledge to set up racks of robotic arms, computer vision systems, and so on.”

This hasn’t stopped new entrants entering the space. The robotics firm Fabric is opening automated fulfillment centers in an effort to compete with Amazon’s warehousing network. The technology brings significant labor efficiency as well as adding flexibility that in turn can make in-city locations worthwhile. Fabric’s Chief Commercial Officer, Steve Hornyak, has stated “It’s not that humans can’t do this .. but you’ve got all these spikes in e-commerce. Robots are very good at spikes, humans are not“, SupplyChainDive reports.

Panjiva data’s shows that growth in industrial robotics investments is returning after a slowdown in much of 2018 and 2019 with growth of 8.3% year over year in the three months to Nov. 30. The decline may reflect uncertainty in business investment triggered by the U.S.-China trade war. The direct impact of tariffs was minimal – indeed Japan is the leading provider with 31.5% of U.S. imports while supplies from China are negligible.

Source: Panjiva

Blockchain – moving from hype to utility

Blockchain is a technology that has been gaining ground in the logistics and trade finance space. Many countries and companies have expressed interest in building alternative payment methods on top of available blockchain platforms. Digital currency has potential for trade financing, where two parties anywhere in the globe can exchange the same currency at a market price. Hong Kong and Thailand recently debuted a two tier digital currency system with the goal of speeding up currency settlement in bilateral trade.

Blockchains have the advantage of being a trusted, decentralized system. The system between Hong Kong and Thailand “overcomes the shortcomings with the existing correspondent banking model, which involves multiple numbers of intermediaries that often results in payment delays“, the South China Morning Post reports.

From a geopolitical perspective the system can provide non-dollarized payment systems – that can prove particularly useful in the face of sanctions as well as reducing outright currency volatility risk, particularly for smaller economies where currencies are less stable.

Tradelens is a block trade platform started by IBM and Maersk that has been gaining members, including container-lines such as Maersk’s 2M Alliance partner MSC as well as rivals including CMA-CGM, Hapag-Lloyd and ZIM Shipping.

This type of growth is essential to a blockchain platform, as sharing data becomes more effective with every new member – the so-called network effect. Recently, Tradelens cleared U.S. antitrust review, allowing the competitors to share data over the blockchain, an essential step to the success of the platform.

The economies of scale make it likely that one platform takes a majority of the market, making it likely that Tradelens will continue to court additional firms. Tradelens already has significant scale and has some data from 43.4% of U.S. ports. Indeed, the volume shipped to ports or terminals participating in Tradelens have tracked close to total U.S. port traffic with a 0.5% slide in the 12 months to Dec. 31 while all other ports were unchanged.

Source: Panjiva

Cyber Security – new systems require new protection

451 Research found in their Voice of the Enterprise 2019 survey that security applications were on the mind of a vast majority of IT leaders – 20% more respondents indicated an increase in budgets for the security category than a decrease. Additionally, 46% of respondents anticipated spending more on IoT applications to improve security.

Significant cyber security events recorded by the Center for Strategic and International Studies have plateaued, only increasing by 1.9% year over year in the twelve months to Dec 31, after a rapid rise since 2017.

The direct costs of lax cyber security can be significant. In 2017 both Maersk and TNT, a Fedex subsidiary, were hit by a ransomware attack called NotPetya. Maersk is estimated to have lost $200-$300 million dollars to the attack, and posted $264 million loss that quarter. Fedex also said the damage from the attack was around $300 million dollars, stating that “the recovery and restoration of TNT Express’s global operations and IT systems has included every facility, hub and depot.”

The direct costs of replacing infrastructure can be dwarfed by the potential for attacks that compromise a firm’s information, customers, or suppliers.

As companies start to interconnect their supply chains, the attack surface they are exposed to grows. A poorly configured MRP or logistics connection could allow an intrude to jump from one company’s systems to the next.

The WannaCry attack used a vulnerability in a Microsoft Windows SMB protocol to spread from computer to computer without being detected. This allowed the worm to spread throughout companies networks. Automaker Renault reportedly lost four days of production according to Auto News. Often, attacks like these can be mitigated through timely updates and employee anti-phishing education.

Another vector that may be impossible to fully prevent is an insider threat. Once a supplier is onboarded into a network, they have the potential to introduce vulnerabilities to downstream customers. This may not be malicious on their part – customers may be at risk a vendor or second tier supplier that has lax security procedures. The U.S. Commerce Department recently proposed a rule to try to prevent these risks – they would be able to block transactions that pose a risk to downstream U.S. supply chains.

Source: Panjiva